KCN Plastic Molding Boosts Team Spirit with Longyan Gutian Tour While Advancing Precision Injection Moulding Excellence

KCN Plastic Molding Boosts Team Spirit with Longyan Gutian Tour While Advancing Precision Injection Moulding Excellence

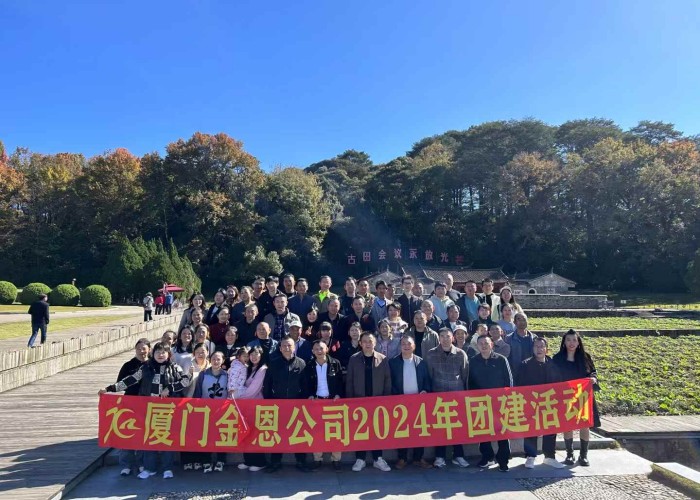

At KCN Plastic Molding (Xiamen Jinjiekun Industrial Co., Ltd.), employee well-being is regarded as a cornerstone of business success. To strengthen team bonds and encourage relaxation outside of work, the company recently organized a memorable tour to Longyan Gutian, a location rich in cultural history and natural beauty. This journey not only gave staff the chance to recharge but also reflected the collaborative spirit that drives KCN’s achievements in the global plastic injection mould industry.

Founded in 2008, KCN has built a reputation as a leading manufacturer of precision plastic injection mould solutions, injection mold tooling, and high-performance plastic injection mould parts. With over 15 years of experience, the company specializes in producing sports equipment accessories, hardware plastic accessories, ABS plastic components, and customized injection moulding plastic products. Operating from its 11,506-square-meter facility in Xiamen, KCN is equipped with 20 advanced plastic injection molding machines, precision tooling equipment, and high-quality printing systems, enabling it to deliver both large-scale production and tailored solutions.

The Longyan Gutian trip provided employees with a much-needed escape from daily routines. Staff explored historical landmarks, scenic mountain views, and cultural heritage sites. Beyond sightseeing, the trip encouraged communication and collaboration across departments—values that are equally important when producing complex injection molds and ensuring precision in every stage of injection moulding plastic manufacturing.

KCN’s leadership emphasized during the trip that teamwork outside the factory translates directly to efficiency and quality inside the factory. Just as the team supported each other during the journey, they bring the same energy and cooperation to designing and manufacturing precision plastic injection mould products that meet international standards.

As an ISO9001-2015 certified manufacturer, KCN follows strict quality management processes. Every plastic injection mould and every set of plastic injection mould parts is produced with meticulous attention to detail, ensuring durability, accuracy, and reliability. By combining advanced technology with skilled technicians, the company continues to achieve an annual output value of 20 million USD, supplying trusted products to clients worldwide.

The Longyan Gutian tour was more than just an employee outing; it was a celebration of the shared values that make KCN a dependable partner for global customers. With strong teamwork, continuous innovation, and a commitment to customer satisfaction, KCN Plastic Molding will continue to lead the way in providing high-quality injection molds and customized injection moulding plastic solutions for industries across the globe.