KCN Plastic Molding Strengthens Team Spirit with Outdoor BBQ Event While Driving Innovation in Injection Moulding

KCN Plastic Molding Strengthens Team Spirit with Outdoor BBQ Event While Driving Innovation in Injection Moulding

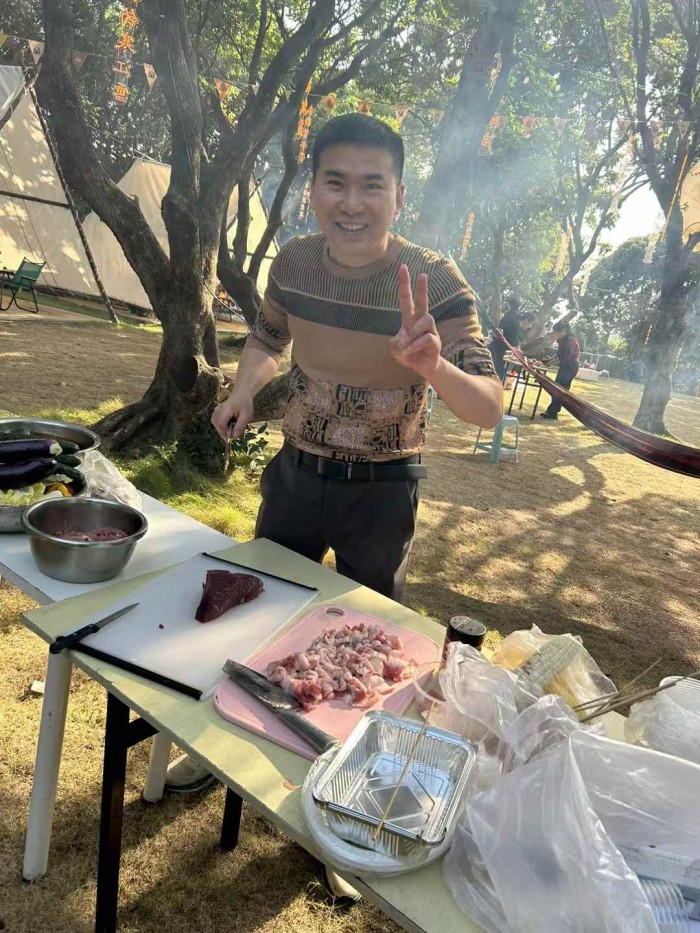

At KCN Plastic Molding (Xiamen Jinjiekun Industrial Co., Ltd.), success is built not only on advanced manufacturing capabilities but also on strong teamwork. Recently, the company organized a lively outdoor BBQ activity for employees, giving the team a chance to relax, bond, and recharge. The event reflected KCN’s belief that a motivated and united workforce is the foundation for delivering excellence in the competitive field of plastic injection mould manufacturing.

Founded in 2008, KCN has grown into a trusted supplier of precision plastic injection mould solutions and high-quality plastic injection mould parts. The company specializes in producing sports equipment accessories, hardware plastic accessories, ABS plastic parts, and custom-designed molds for global clients. With more than 15 years of industry experience, KCN operates out of a modern 11,506-square-meter facility at No. 7 Guangxing South Road, Xiamen. Its plant is equipped with 20 advanced injection molding machines, as well as precision tooling and printing equipment that allow for large-scale, high-quality production.

The BBQ gathering provided employees with more than just delicious food and a festive atmosphere. It was an opportunity for team members from different departments—including mold design, production, and quality control—to connect outside the workplace. This spirit of unity mirrors how KCN approaches its projects: combining expertise across departments to deliver reliable and innovative injection moulding plastic solutions.

Quality and precision remain at the heart of KCN’s operations. The company has achieved ISO9001-2015 certification, ensuring that every injection mold and every batch of plastic injection mould parts meets international quality standards. From design to prototype development to full-scale manufacturing, KCN provides one-stop services for clients seeking dependable and cost-effective solutions.

During the BBQ event, company leaders emphasized that the same teamwork celebrated at the grill translates directly into the workshop floor. By encouraging open communication and fostering a supportive culture, KCN ensures that employees remain motivated to pursue technical innovation and continuous improvement.

Looking ahead, KCN is committed to strengthening its role as a leading plastic injection mould supplier for international markets. With a growing annual output value of 20 million USD, the company is well-positioned to expand its reach and support global customers who require high-performance precision plastic injection mould products and reliable injection moulding plastic services.

The outdoor BBQ was more than a company celebration—it was a reminder of the values that drive KCN: unity, innovation, and customer focus. As the smoke from the grill faded into the evening sky, the message was clear: with strong teamwork and cutting-edge technology, KCN Plastic Molding will continue to deliver world-class injection molds and plastic components for industries worldwide.