Basic Knowledge That Must Be Mastered in Injection Mold Design 1

The mold is divided into several major systems:

Pouring → Ejection → Cooling →Molding→ Exhaust

Common defects in plastic parts:

Short molding→burrs→bubble→shrinkage→weld mark→black dots→stripe→lifting→delamination→peeling

What problems should be paid attention to in the process of plastic injection mold design?

1、The wall thickness should be as uniform as possible, and the draft angle should be large;

2、The transition part should be gradual and smooth transition;

3、The gate and runner are as wide as possible, thick and short, and the gate position should be set according to shorten the condensation process, and if necessary, a cold well should be added;

4、The surface of the mold should be bright, with low roughness (preferably lower than 0.8;

5、There must be enough vent holes and vent slots to discharge the air and gas in the melt in time;

6、Except for PET, the wall thickness should not be too thin, generally not less than 1mm.

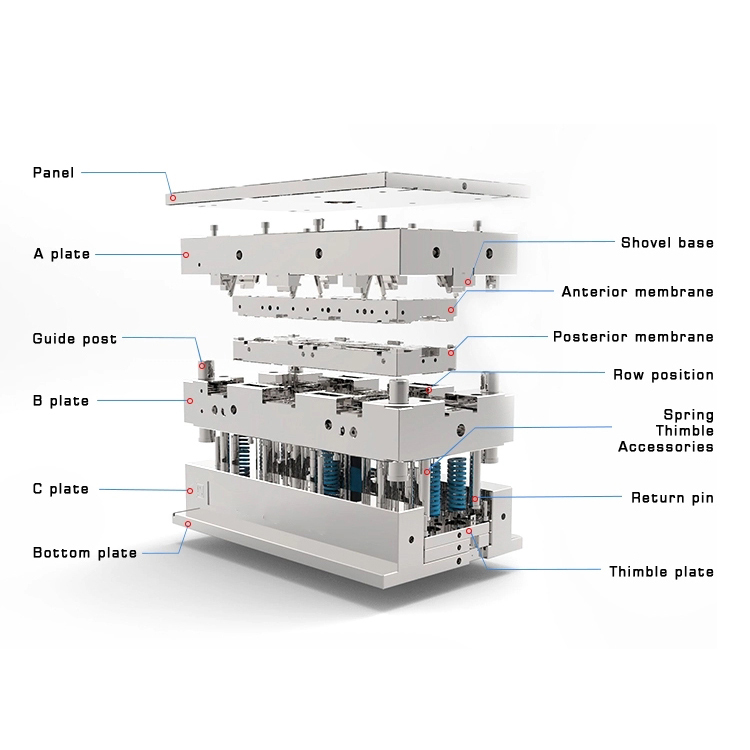

What are the structures of the mold base?

op clamping plate → A plate → B plate → spacer block → guide post → ejector plate → ejector fixing plate → bottom clamping plate

What are the basic forms of the parting surface?

Straight→Skewed→Curved→Straight→Curved

How to hide each other in UG?

ctrL+B or ctrL+shift+B

What are the mold processing machinery and equipment?

CNC→Lathe→Milling Machine→Grinding Machine→Drilling Machine