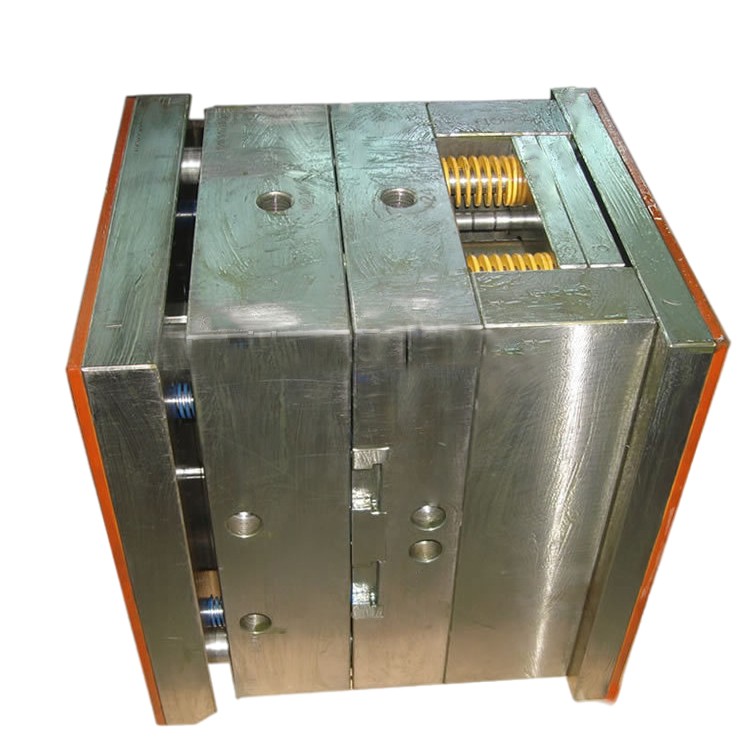

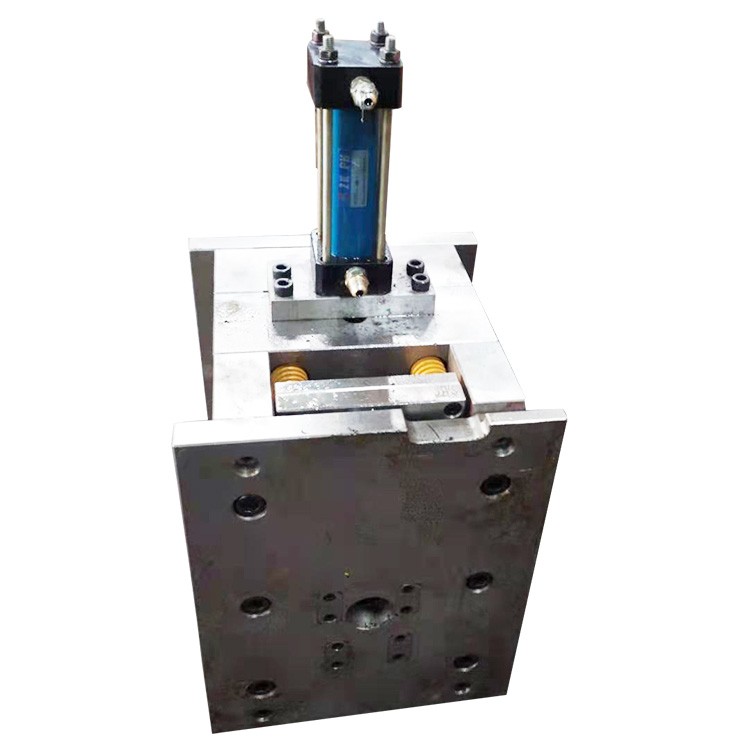

Plastic Injection Mould

-

Universal Moulding ABS Plastic Injection Mould

1. Continuance service and support :

Email Details

Can provide one-stop service from mold design, mold tooling, injection production, screen printing, spray paint to assembly;

2. Diversified rich experienced skilled workers:

More than 15 years experiences in plastic injection and plastic injection mold and advance management;

3. Custom R&D program coordination:

With more than 10 engineers for mold design, programming and project managers. We are using CAD/CAE/CAM software to do the design, analysis & programming.

4. Quality, reliability and long product life:

We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment and strict quality management system to ensure the quantity and quality. -

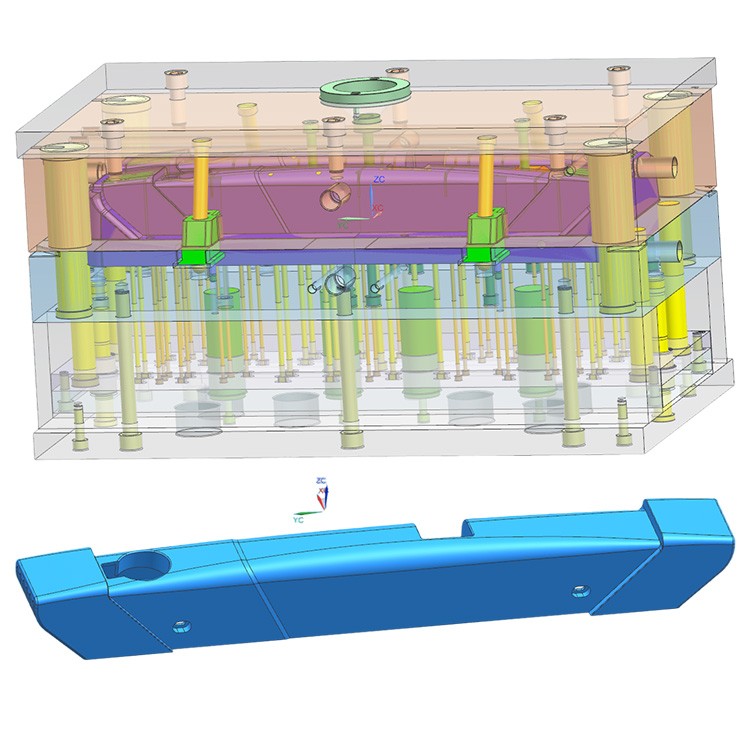

Universal Injection Mould Plastic Molding

1.Start from part design analysis;

Email Details

2.Mold design drawing and DFM report available so you can see how is the mold going to be before mold making;

3.If product is complex,moldflow report will be present as well;

4.In house mold making shop ensure you mold quality under well control;

5.Normally it takes 20-40 days to make mold,precise time depends on part design;

6.Can provide one-stop service for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services. -

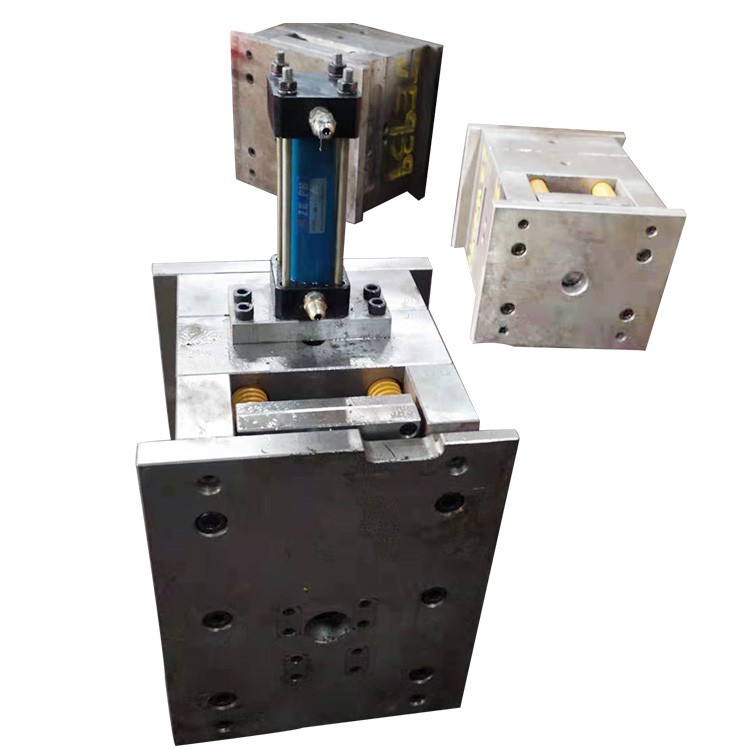

Cold Hot Runner Precision Plastic Injection Mould

Advance Service before sales

Email Details

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization suggestions

Advantages of tech teams

1.More than 800 sets per year mold making enable us to have rich experience across kinds of industries.

2. Enough and advance equipments for customer product characteristics.

3. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

Advantages of after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment. -

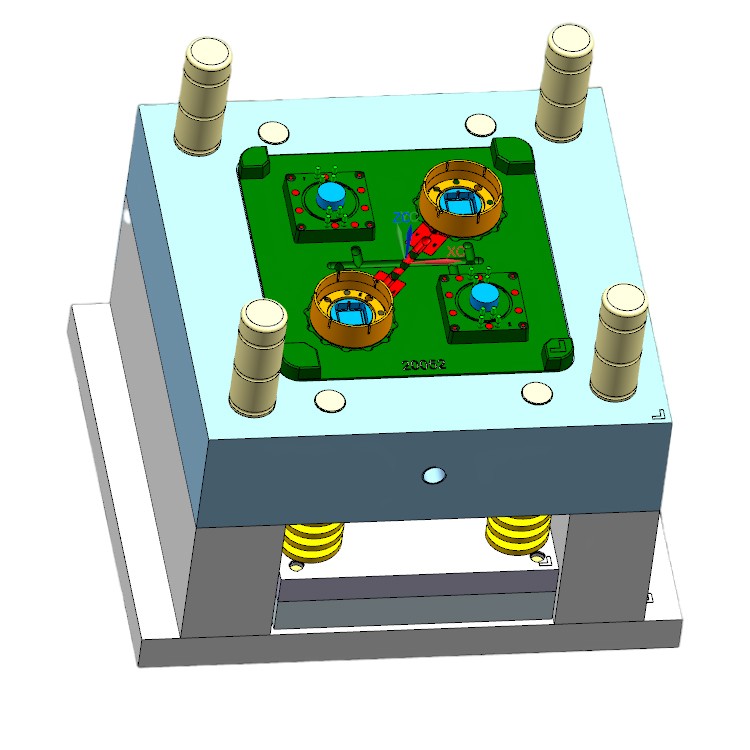

Custom Injection Moulding Plastic Mould

1. Design Service:

Email Details

With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

2. Guaranteed delivery:

(1) Have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment.

(2) Our workshop area is about 7500 square meters;

(3) Provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

3. Strict quality management system:

(1) Material inspection--Check the material surface and roughly dimension.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment. -

Injection Molding Precision Injection Plastic Mould

1. High quality and factory price for plastic injection mould service;

Email Details

2. Plastic injection mould design and making service and plastic injection service for over 30 countries; Provide high-volume injection molding solutions;

3. One-stop service from plastic injection mould making to plastic injection and assembly;

4. Collaboration during the mold design process between our customers, management, and our employees to implement the best possible concept;

5. Our unique capacity to create solutions that replace expensive, fabricated steel products. -

OEM Or ODM Injection Parts Injection Plastic Mould

1. Manufacturing experience for more than 15 years and exporting experience for nearly 8 years. ISO 9001 approved

Email Details

2. Products are supplied to over 20 countries.

3. One-stop service for plastic injection products and plastic injection mold making.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. Professional design team, mold maker engineer. OEM/ODM service.

8. Professional QC and R&D teams to assure high quality. -

Custom Mold Injection Plastic Mold

Advance Pre-sale service

Email Details

1. Your drawing will be checked carefully or do the design for you by our professional and experienced engineer team;

2. Most of the materials or colors as your requirement.

3. Good Quality, Factory Price ,Quick Response and Reliable Service will offer you.

Advance after you choose:

1. Design the mold drawing and provide DFM report.

2. Update the videos and pictures of each process of your order to check the quality.

3. Offer free samples for your check and confirm.

Advance after-sale service

1. We are very glad that customers give us some suggestions for price and products.

2. If you have any questions, please feel free to contact us by E-mail or Telephone. -

Hot

Lunch Box

Product Description

Email Details

Plastic food container/lunch box injection mold with competitive price/mold/injection mold

1. Function: Use molds to produce plastic containers

2. Mold material: H13 vacuum quenching

3. Runner: hot runner

4. Number of cavities: 1

5. Injection molding machine: 280 tons

6. Mold life: 1000000

7. Delivery time: within 45 days

Our advantage.

1. Good quality and competitive price

2. Have rich design experience to satisfy you!

3. After receiving your inquiry, we will help you quote as soon as possible.

4. Prepare mold materials in advance and complete the mold on time.

5. We will send you work reports every week so that you can understand our mold progress.

6. Free trial samples sent to your country for confirmation.

7. Pack the mold and prepare everything for mold shipment.

8. Diligence, sincerity, honesty and responsibility are our character. -

Universal Plastic Injection Mould For Plastic Products

(1) Use the brand material, like "Mitsubishi" to make sure the quality.

Email Details

(2) 10 Lines with Big capacity-cost-effective and flexible to adjust production for volume and urgent orders.

(3) Strict QC during producing to control the quality.

(4) Choose high precision mold and advance plastic injection machine to make sure the high glossy and stable quality, high optical polished surface quality, low surface roughness average, thickness tolerance control is good.

(5) 15-year factory experienced in plastic mold and plastic injection and with strong customization capacity, satisfy your requirement to the best.