OEM Or ODM Injection Parts Injection Plastic Mould

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. Manufacturing experience for more than 15 years and exporting experience for nearly 8 years. ISO 9001 approved

2. Products are supplied to over 20 countries.

3. One-stop service for plastic injection products and plastic injection mold making.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. Professional design team, mold maker engineer. OEM/ODM service.

8. Professional QC and R&D teams to assure high quality.

OEM Or ODM Injection Parts Injection Plastic Mould

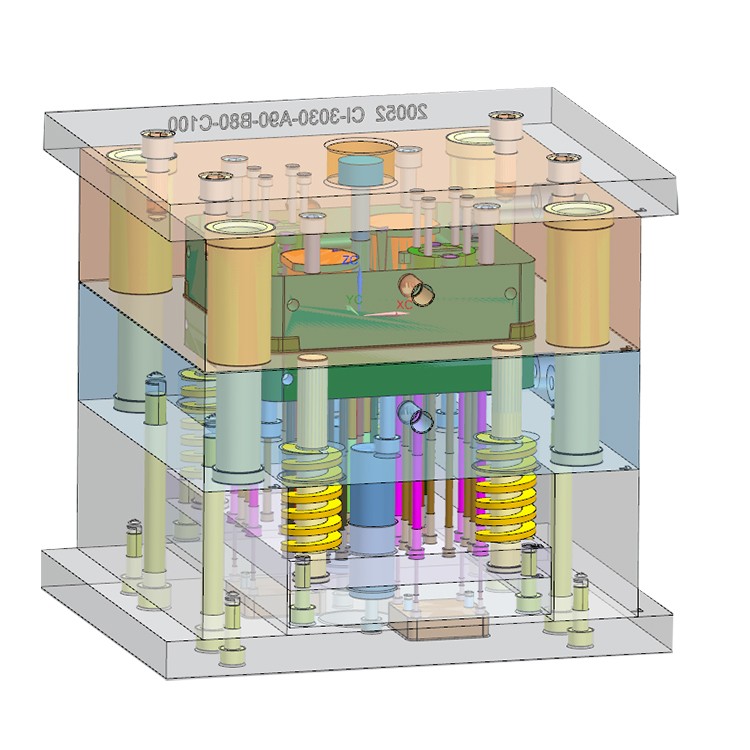

Plastic Injection Mould Specification:

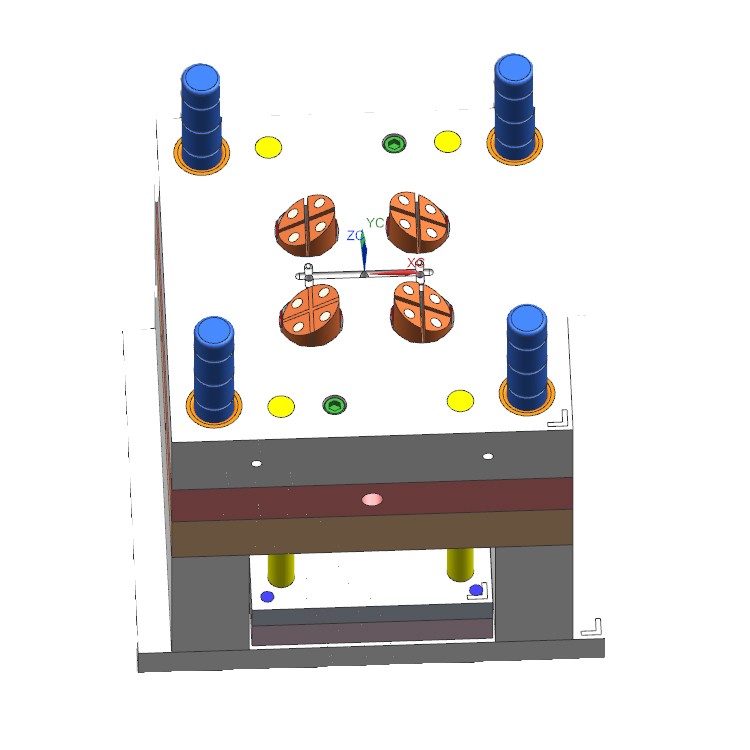

Ejector system | Stripper plate,Lifter,Push bar,Ejection pin etc. |

Inserts(cavity and core) | H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or as your request |

Mold cavity | 1*1,1+1,1*2,1+1+1,etc. |

Injection system | Hot/cold runner |

Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc. |

Steel for mould | P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc. |

Steel standard | FINKL,Assab,DAIDO,LKM,Buderus |

Cooling | Baffles/Sprin Piple/3D printing water line |

Design capability | DFM,Mould flow analysis,Product optimization, Full 2D & 3D mould design,Reverse engineering,Collaborative design with customer's idea |

Documents / Reports Provided | Fully drawing,Weekly Processing Report, Steel Dimension report, Processing Report,Sample Dimension Report. |

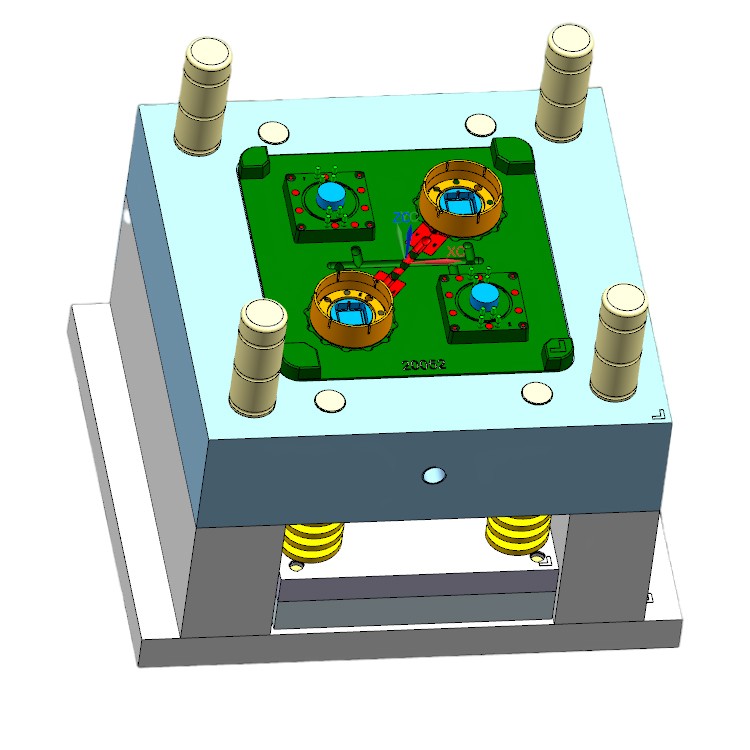

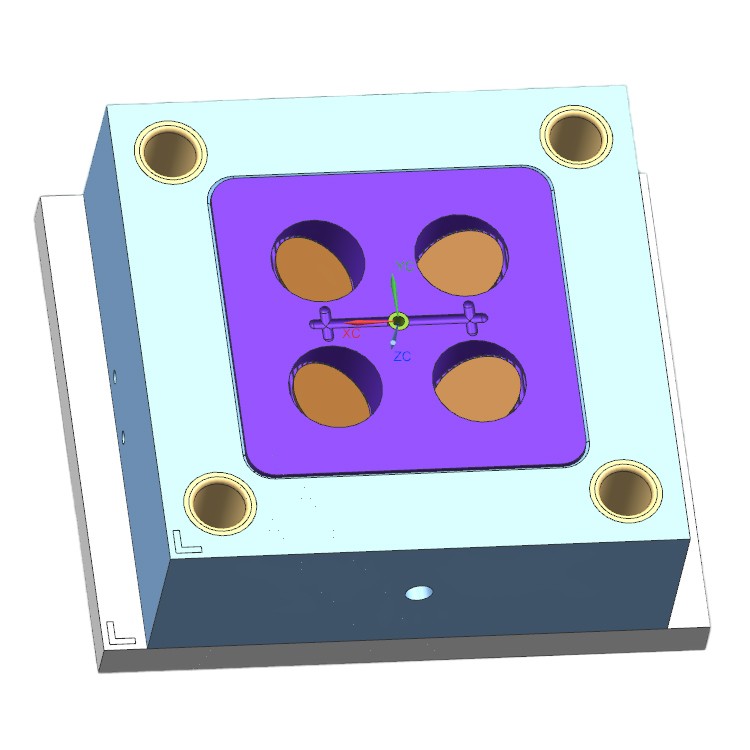

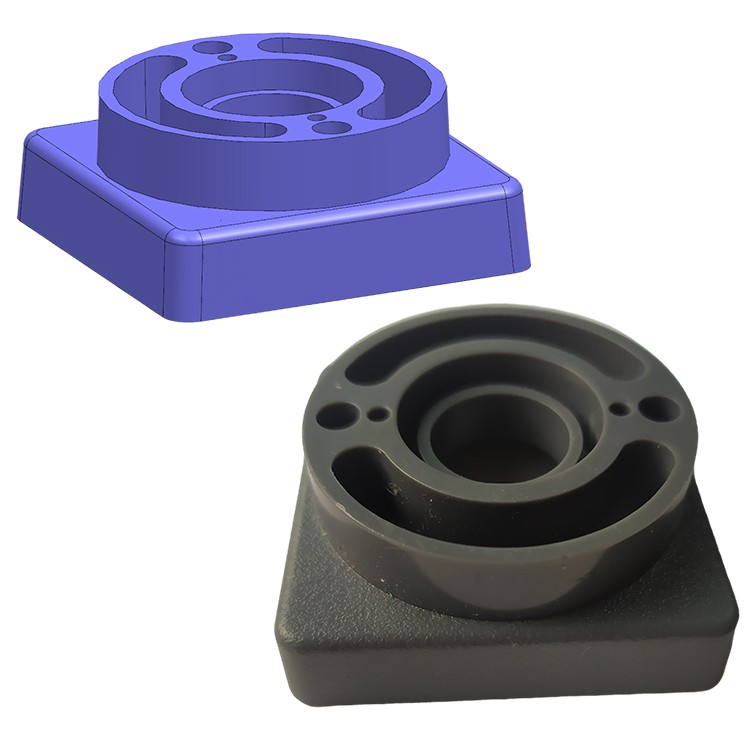

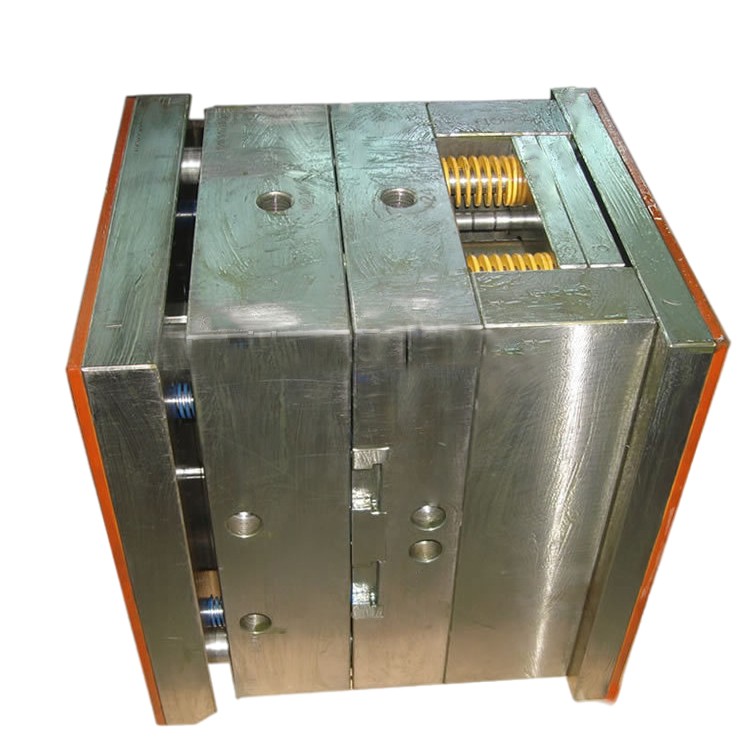

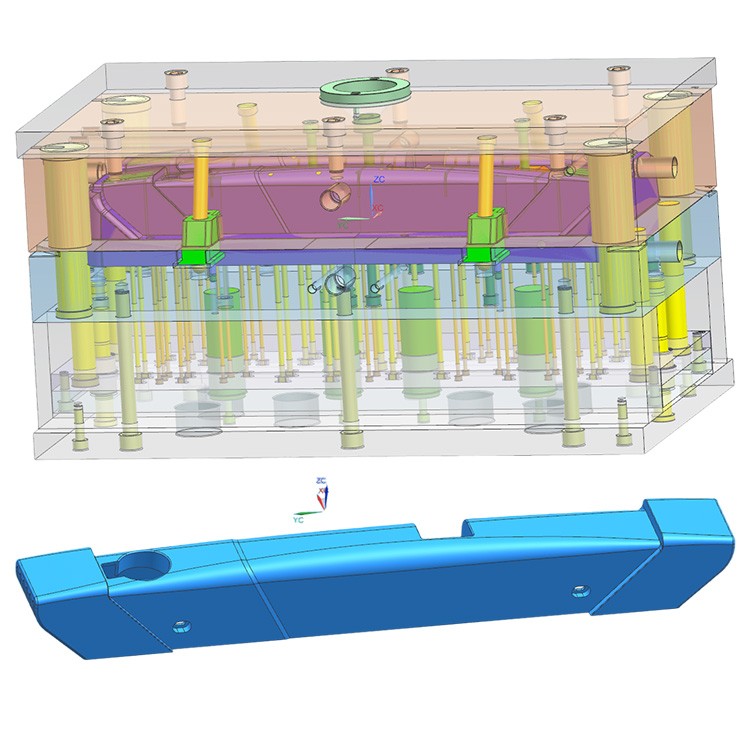

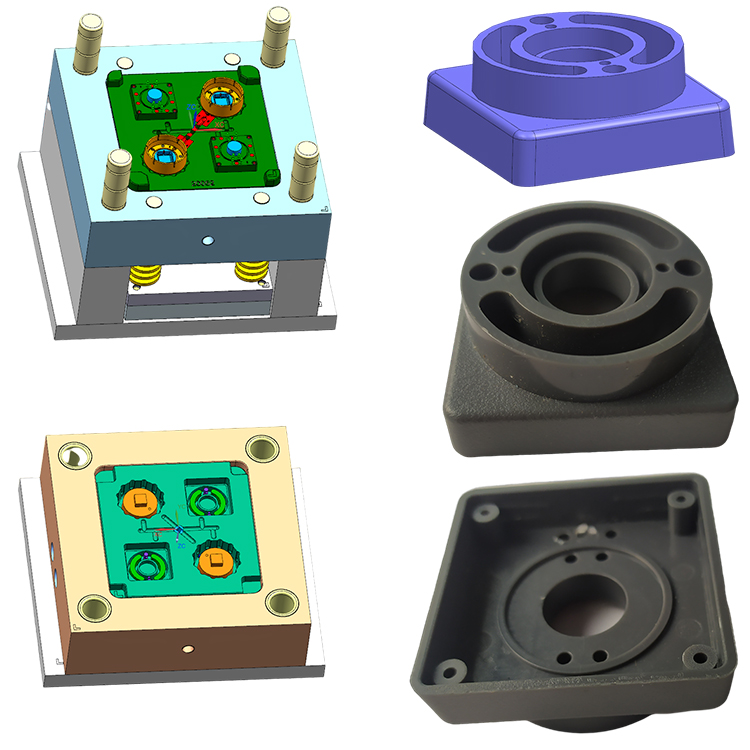

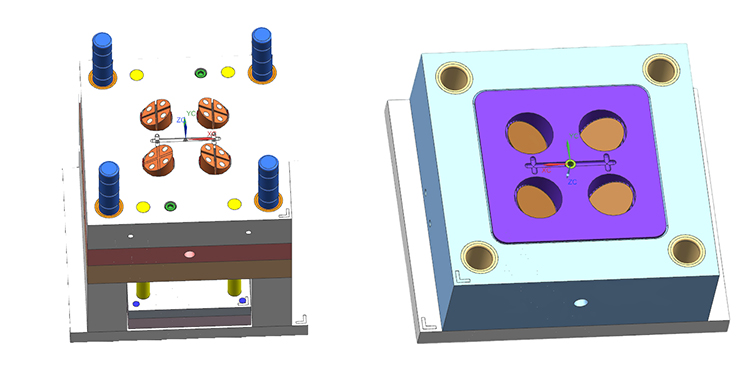

Plastic Injection Mould and Products Show:

Plastic Injection Mould Feature and Application:

1. Efficiency production and automotive operation;

2. Shape can be from simple to complex, the size can be from large to small and the product size is accurate;

3. It is used in the forming and processing fields of mass production and products with complex shapes.

The moulds we make involves house appliance, fitness equipment, electronics, industrial, auto parts, bathroom, medical, over molding and so on.

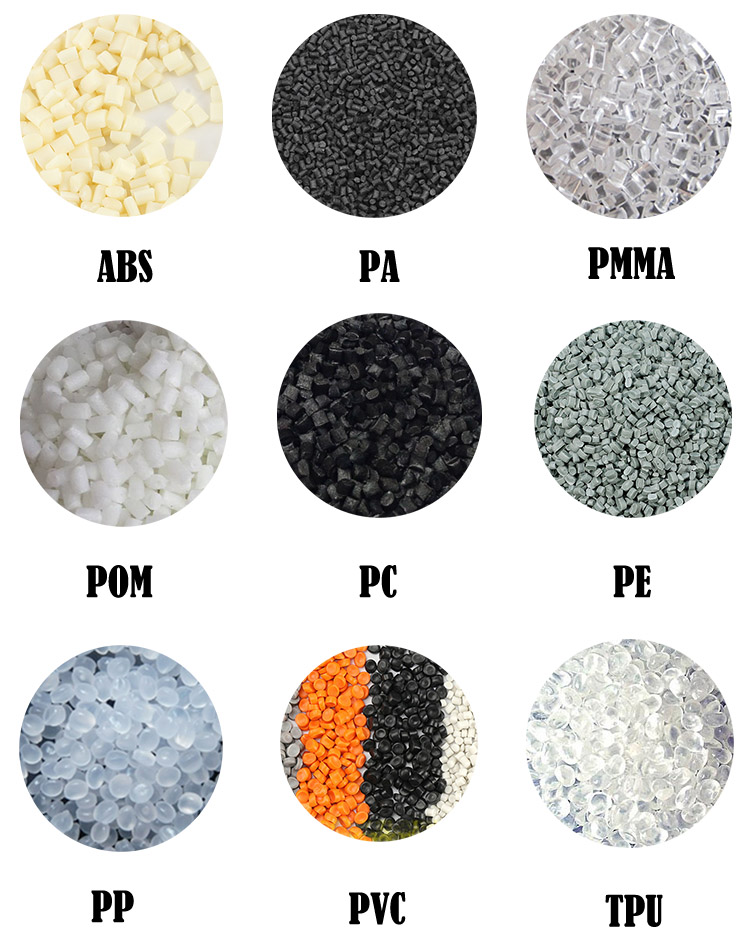

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Our Plastic Injection Mould Case Show:

Payment and Shipping:

We accept many kinds of the payment, the details as the following:

1. For the samples, we can accept PayPal, West Union and Bank Transfer as the payment, and will ship the samples by air express, such as the DHL, UPS and FEDEX.

2. For the bulk order, we can suggest the bank transfer as the payment method with the 30% deposit, we will ship out the goods according to the choice from the customers for shipping.

3. We can ensure the shipping is fast and efficient.