Plastic Injection Molds Exhaust System Design

Plastic injection molds exhaust Measures:

In the injection molding process, the gases that need to be exhausted include water vapor in the melt due to poor drying, air in the mold cavity, volatilized gases that are easy to develop in the raw materials, and materials decomposing and decomposing gases etc.

Plastic injection molds exhaust system must ensure exhaust smoothly and orderly, its design is main depended on experience and make it perfect though the trial mold and repair.

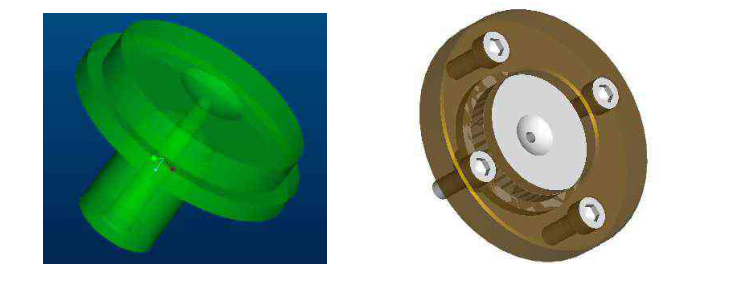

Fox example, there is a design of a small part. We used the fit gap between the accessories of mold and parting surface to exhaust, the fit gap of mold parting surface fitting to exhaust, the fit gap between roll out parts and mold plate slide fitting to exhaust and shaping parts, shaping inserts etc. fitting to exhaust.

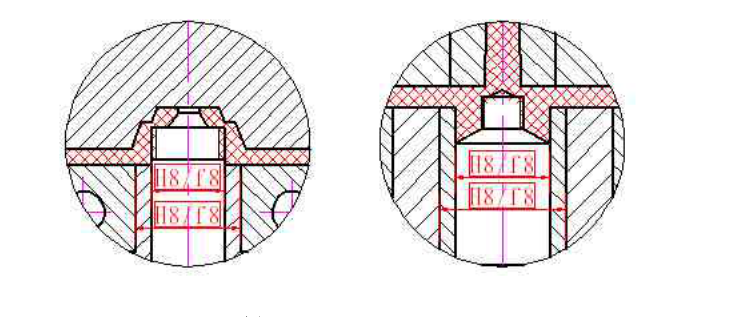

Check the following picture, used the fit gap of thread core and shaft sleeve fitting(H8/f8), the fit gap of shaft and cavity fitting(H8/f8) to exhaust. With this way, the mold structure is simple and the exhaust effect of the mold is also very well.