What Are the Components of an Injection Mold?

What Are the Components of an Injection Mold?

In the world of modern manufacturing, plastic injection mould technology plays a vital role in producing everyday products, from automotive parts to household items and sports equipment. At the heart of the injection moulding plastic process lies the injection mold itself. Understanding its structure is essential for engineers, designers, and even customers who rely on high-quality plastic injection mould parts. So, what are the main components of an injection mold, and how do they work together?

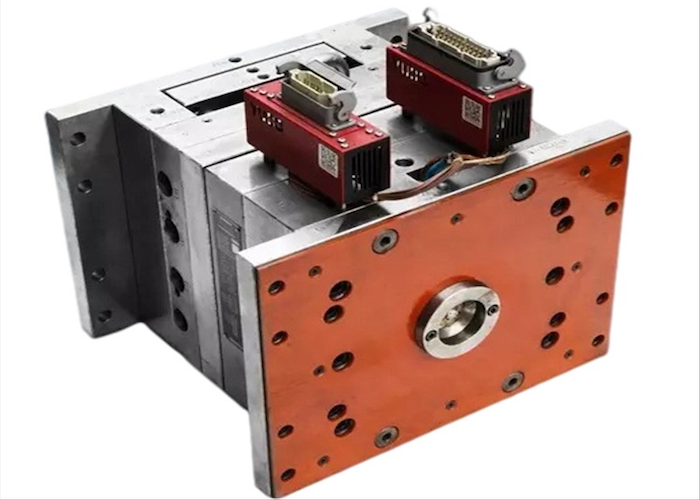

1. Mold Base

The mold base is the foundation that holds all the other components. It provides stability and alignment during production. A strong mold base ensures durability and consistency, especially for high-volume production of precision plastic injection mould parts.

2. Core and Cavity

The core and cavity are the two essential halves of the mold that shape the plastic. The cavity forms the outer shape, while the core forms the inner structure. When molten plastic is injected, it fills the space between the core and cavity, solidifying into the desired part. This section determines the accuracy of the injection mold, which is why precision machining is critical.

3. Runner System

The runner system delivers molten plastic into the cavity. It includes sprues, runners, and gates that guide material flow. In advanced precision plastic injection mould design, hot runner systems are often used to reduce waste and improve efficiency.

4. Cooling System

Plastic must cool quickly to maintain part accuracy and cycle efficiency. Cooling channels are built into the mold, circulating water or oil to remove heat. Proper cooling ensures consistent quality of plastic injection mould parts and reduces defects like warping or shrinkage.

5. Ejector System

Once the part solidifies, it must be removed from the mold. The ejector system—usually ejector pins, sleeves, or plates—pushes the part out smoothly without causing damage. This is an essential part of the injection moulding plastic process, as it directly affects product quality.

6. Venting System

Air trapped in the mold can cause defects such as burn marks or incomplete filling. Vents allow air and gas to escape during injection, ensuring smooth filling of the plastic injection mould cavity.

Why Understanding Mold Components Matters

For manufacturers and clients, knowing the components of an injection mold helps ensure better communication, cost efficiency, and quality control. Each element—from the mold base to the ejector system—plays a role in achieving precise and reliable plastic injection mould parts.

At KCN Plastic Molding, our team of experienced technicians combines advanced equipment with over 15 years of expertise in precision plastic injection mould production. By focusing on design, tooling, and quality management, we deliver reliable solutions for global clients across industries.