ABS PC PP Plastic Molded Injection Parts

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

Professional experience in one-stop solution on tooling and production;

Satisfy the precision mold requirement in wide rage industry;

Can do from mold design to manufacturing.

1. Fast Quote:

With more than 10 engineers, for mold design, programming, project managers, we are using CAD/CAE/CAM software to do the design, analysis & programming, to guarantee the satisfaction of customers.

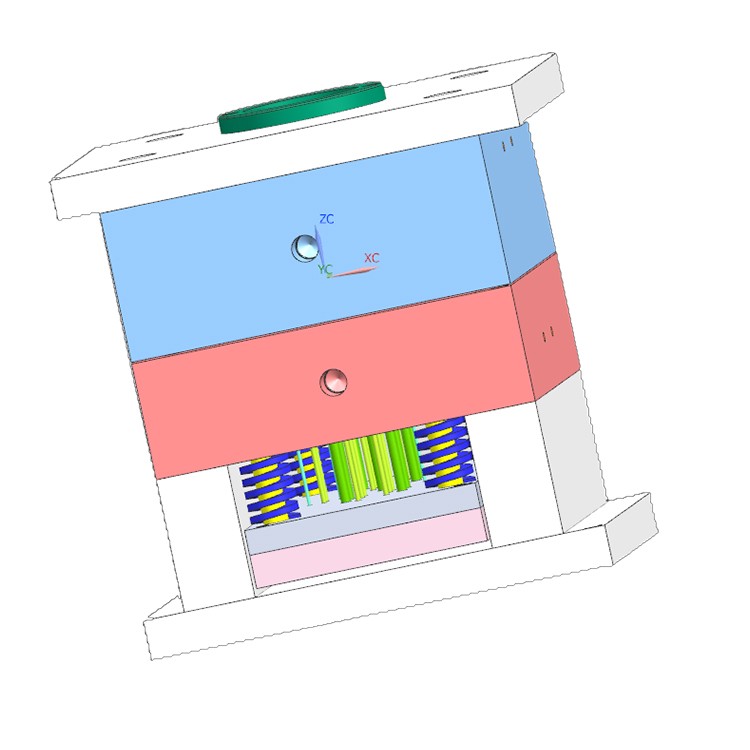

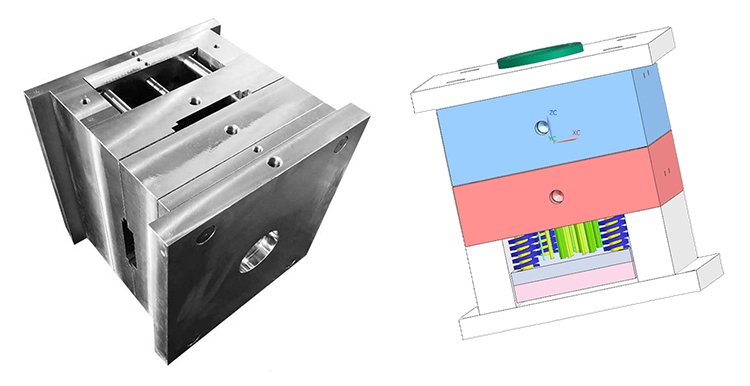

2. Mold Design and Making:

Advance injection mold machine to ensure the quality; Injection mold, stamping die & die casting as well;

3. Plastic Injection Products Production:

Enough and many kinds of injection machines to ensure the quantity;

4. Secondary Process:

We can provide ONE-STOP SERVICE for plastic product customizing works. We provide mold design, precision plastic mold making, custom best quality plastic injection molding, Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services;

5. After Service:

For your smoothly running machine or product use.

ABS PC PP Plastic Molded Injection Parts

Plastic Injection Products Specification:

Mould base | Standard mould base, LKM, HASCO etc. |

Cavity | Single/multi |

Runner | Hot/cold |

Design software | UG, PROE, CAD, CAXA etc. |

Surface treatment | Polish, texture, sand blasting, chrome plating |

Mould life | 300,000-1,000,000 shots |

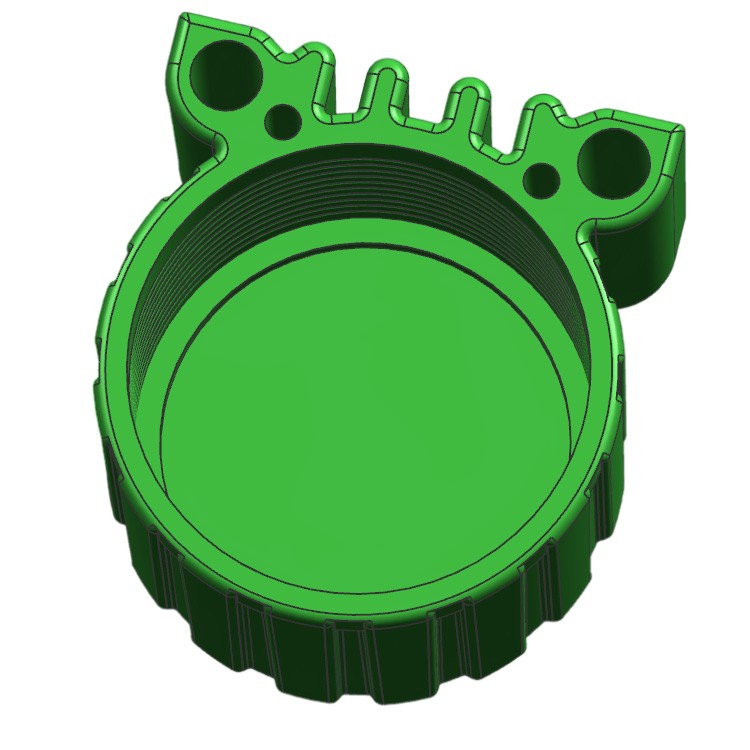

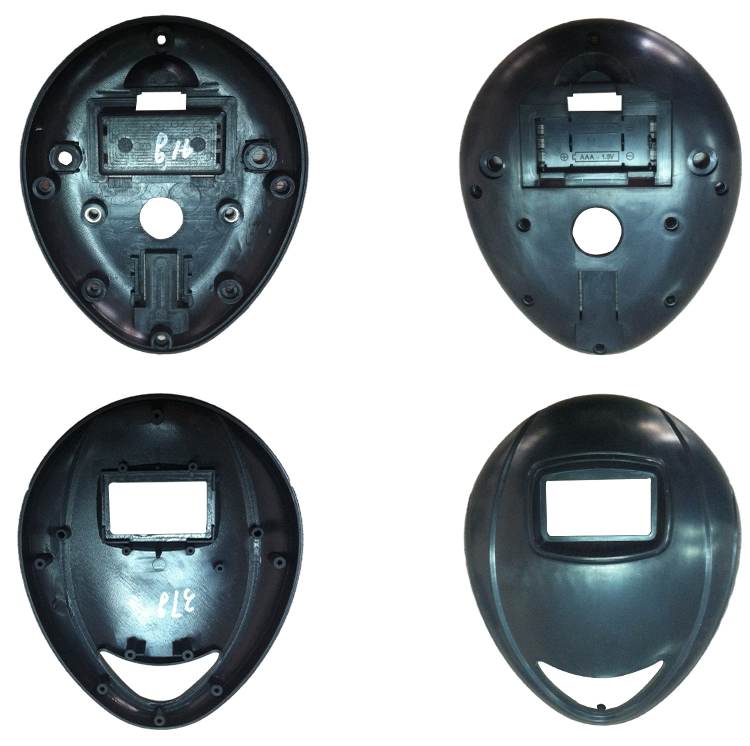

Plastic Injection Products Picture:

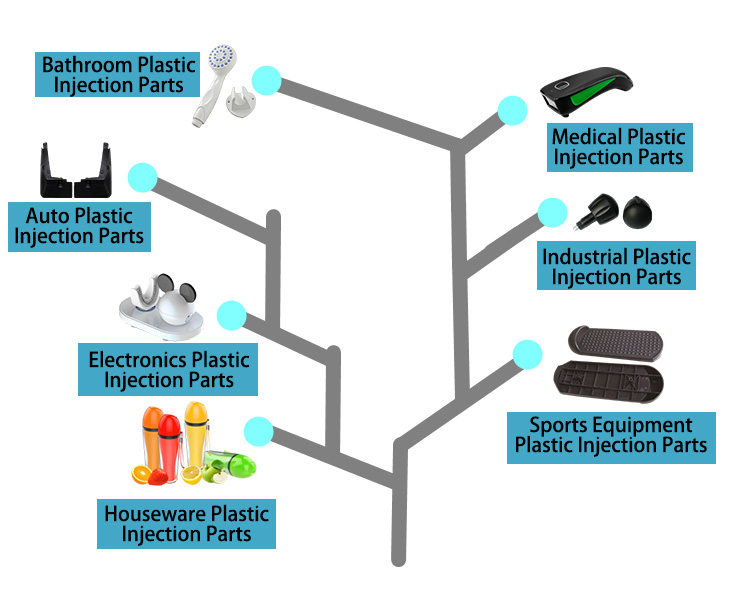

Plastic Injection Products Feature and Application:

1. Efficiency production and automotive operation;

2. Shape can be from simple to complex, the size can be from large to small and the product size is accurate;

3. It is used in the forming and processing fields of mass production and products with complex shapes.

The moulds we make involves house appliance, fitness equipment, electronics, industrial, auto parts, bathroom, medical, over molding and so on.

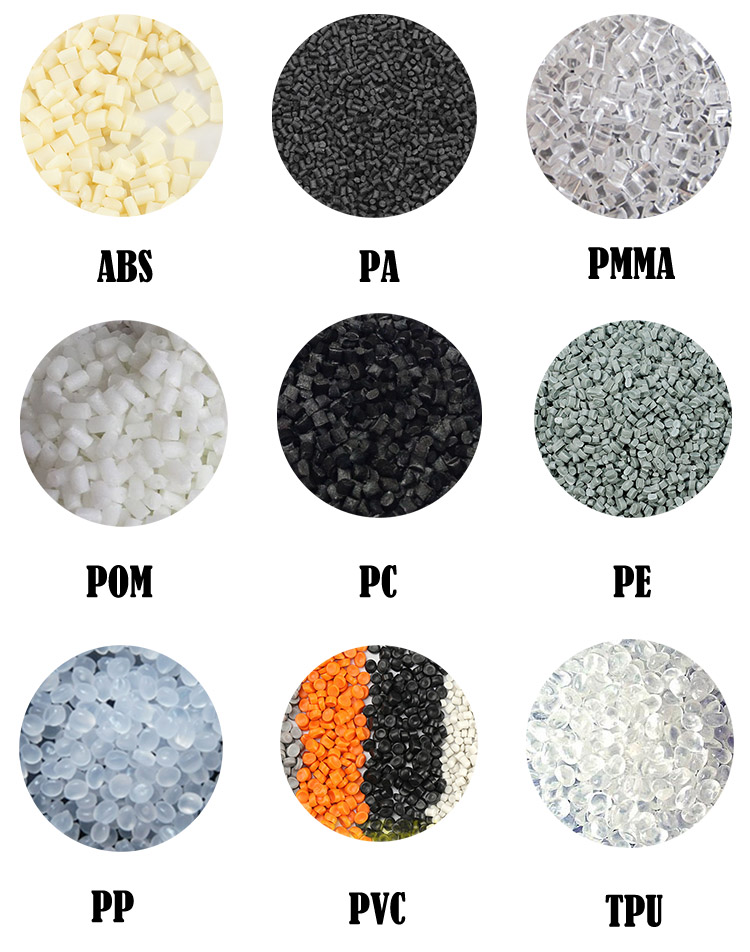

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Our Plastic Parts Case Show:

FAQ About Molded Products:

Q1: How many injection plastic mouldings machines do you have?

A1: We have more than 50 sets of plastic Injection Mouldings machines.

Q2: what is the minimum & maximum unit weight and size your machines can produce?

A2: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q3: What kind of plastic materials you usually use?

A3: We are specialized in producing plastic products with the following materials: PP, ABS, PC, POM, PA, HDPE, HIPE, PS, AS, PBT, PET, PMMA, PVC and so on.