Homeware Injection Molding Plastic Mould

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1) We are a professional OEM&ODM plastic injection mold manufacturer;

2) We have a team with experienced engineers and quality control team as our strong backing;

3) High quality, competitive price, quick response;

4) Professional technical support;

5) Quick response;

6) A strict quality control process;

7) High-cost performance;

8) More than 15 years experience in plastic injection mold and plastic injection;

9) ISO/ERP system guarantee.

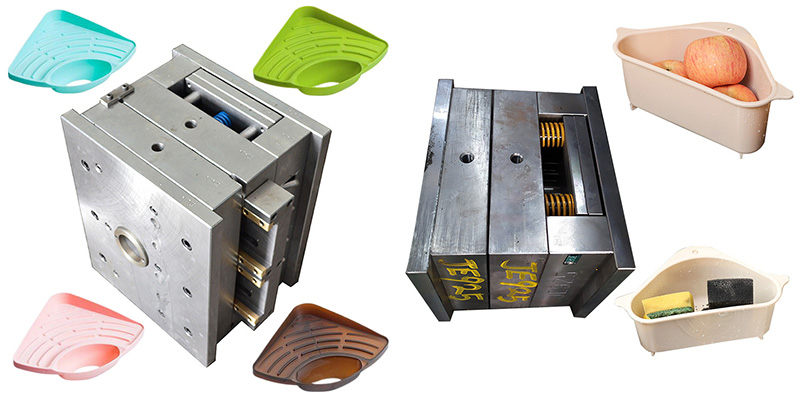

Homeware Injection Molding Plastic Mould

Plastic Households Mould Specification:

Mould Base Material | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

Mold Accuracy | +/-0.001mm |

Mold Life | 50K-1.5Million Shots |

Hot runner/Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 60 to 950ton plastic injection machines |

Feature: | Non marking and Non flash |

Surface Treatmetn | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

Product Name | Homeware Injection Molding Plastic Mould |

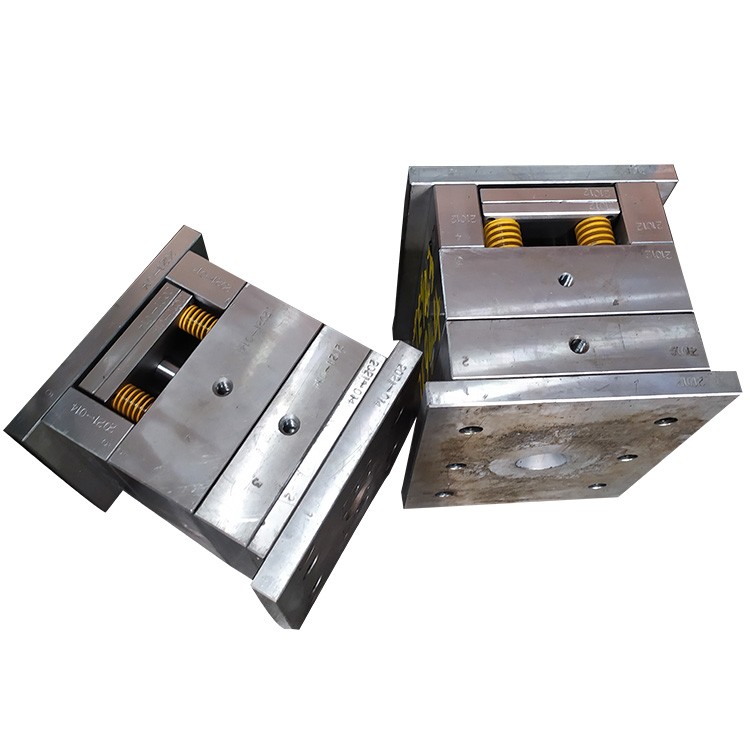

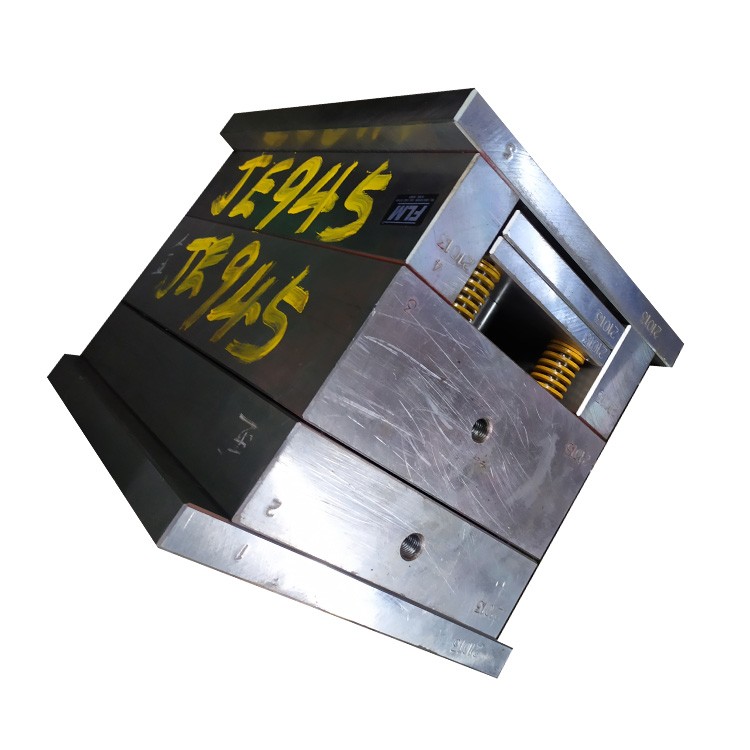

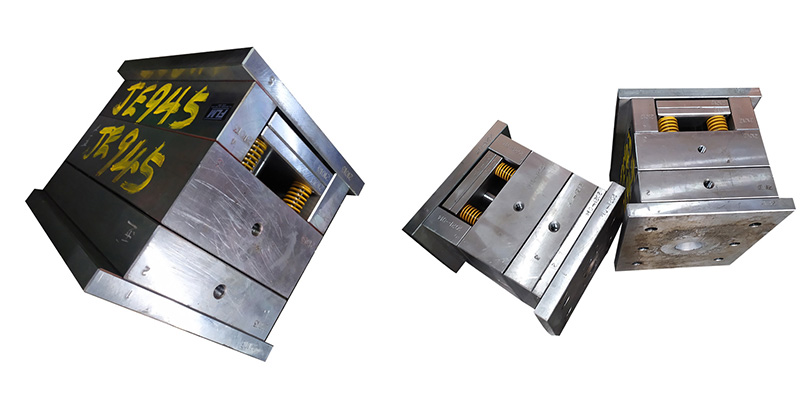

Plastic Households Mould Picture:

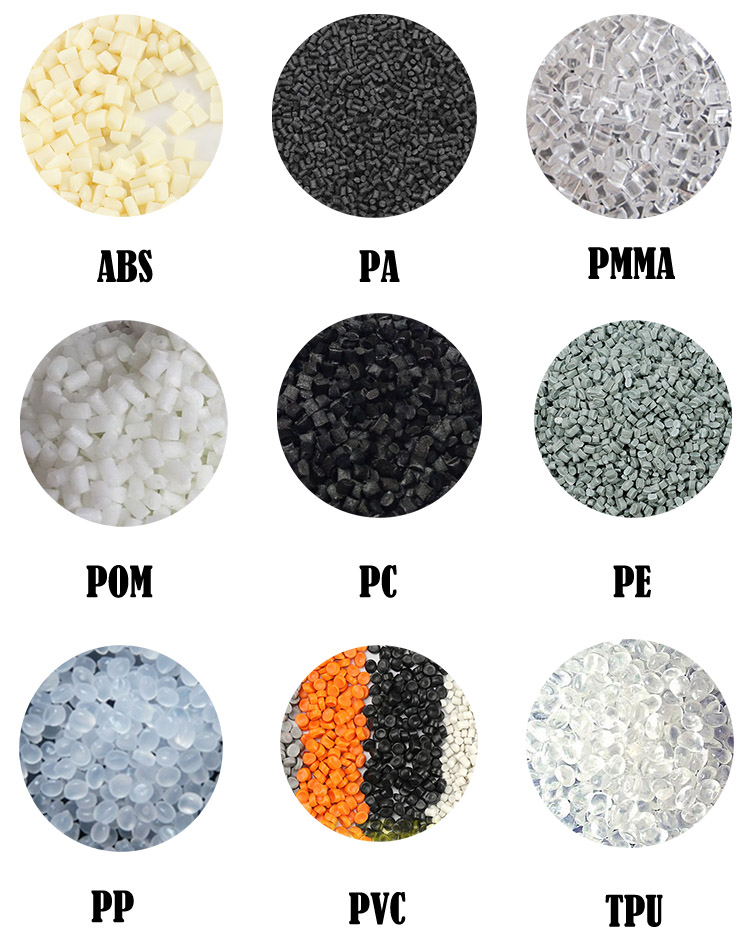

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Plastic Households Mould Manufacturer Information:

We were established in 2001 (Its formerly is Xiamen King trade Co., Ltd.). We are a manufacturer of Plastic injection mould and plastic products express in plastic parts of sport equipment. Now we are one of the important manufacturers in sport equipment industry. We also produce and sales plastic households products and plastic electronic products.

We are located in Xinglin development, Jimei district zone, Xiamen City. We have 20 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. Our workshop area is about 7500 square meters and we have precision production equipment which reach the international advanced level and the experienced technician. Now our production value can reach 1.4 Billion RMB. “Quality first, continuous improvement, respect individual, team spirit” is our top management objective. We will make “build quality brand, service the needs of customers” as our guiding ideology. In connection with the requirement of domestic market and international market, we will take “excellent quality, perfect service” to meet the challenge actively to achieve our company top management goal --- continuity progress.

Product Qualification and Certificate:

Packaging and Shipping:

We will be coated one -layer anti-rist oil first, and then also will be covered thin filmson the mould, finally pack into non-fumigation wooden case.

Standard exported Wooden case packed, Fumigation process(upon required).

FAQ:

Q: How you do the quality control?

A:

1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out.

Q: How long is the lead-time for a plastic injection mold?

A: It all depends on the mold's size and complexity. Normally, the lead time is 25-45 days. If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q: Can you deliver the plastic moulds or plastic products to our factory?

A: Yes, We have cooperated with many international logistics companies for years. And we have full experience to manage the delivery directly to the client's factory or appointed warehouse.