Plastic Injection Parts Mold For Bathroom Shower

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. We have our own tooling shop, equipped with advanced machines for plastic injection mould and the plastic injection products.

2. We also have their own injection shop, to run the mold test & mass production for customers.

3. We have more than 15years experience for plastic injection mould and plastic injection.

4. We have precision production equipment which reach the international advanced level and the experienced technician.

5. ISO 9001 Certified for all of our plastic injection mould and plastic injection products and our factory;

Plastic Injection Parts Mold for Bathroom Shower

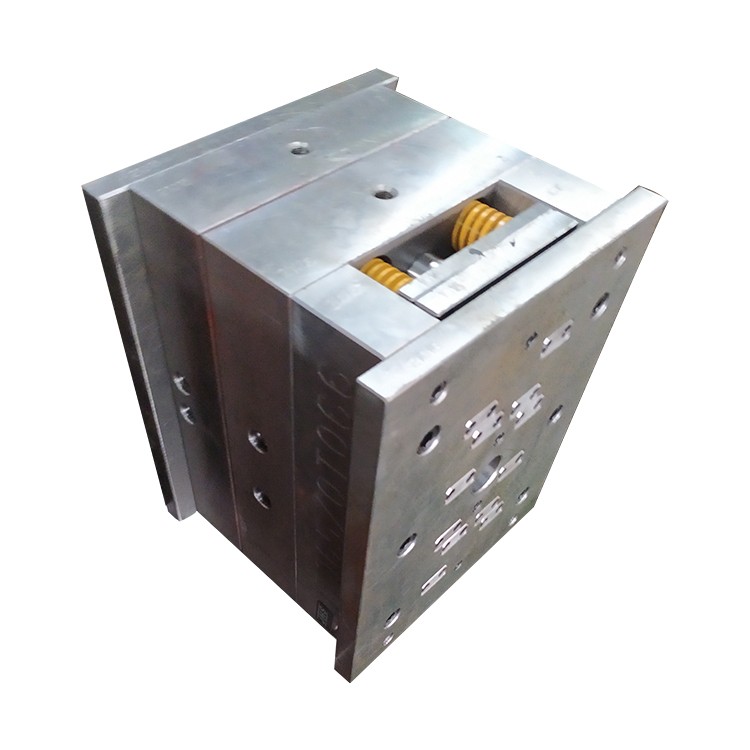

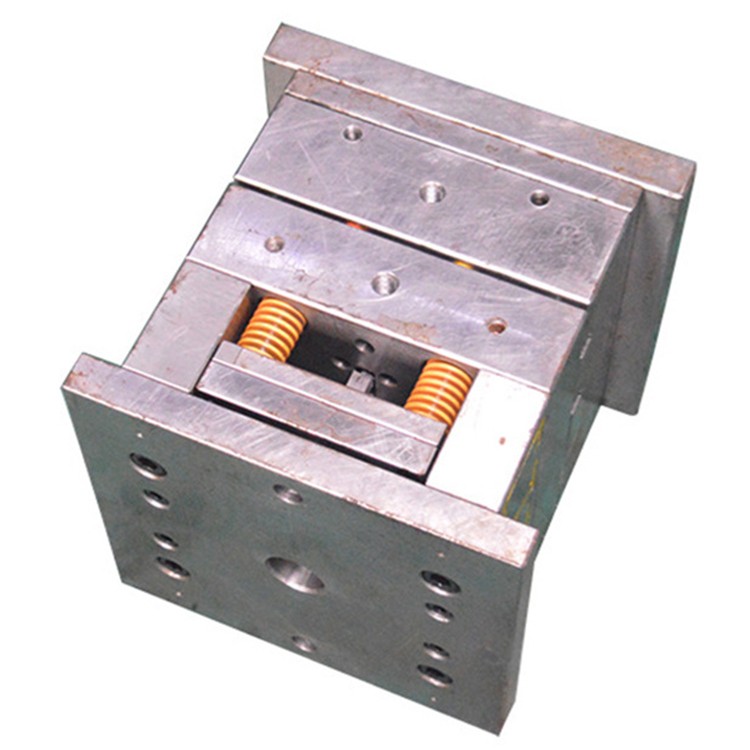

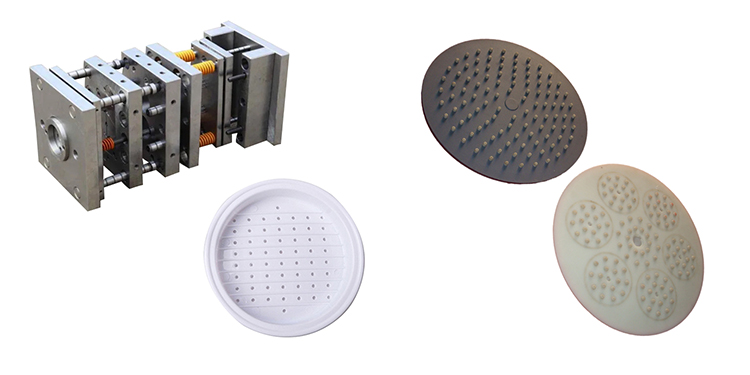

Plastic Bathroom Mould and Product Show:

Plastic Bathroom Mould Description:

| Steel of Cavity & Core | DIN 1.2316/ DIN 1.2738/DIN 1.2344 /M300/ 718/ P20..etc |

| Steel of Mouldbase | S50C.LkM standard…etc |

| Hardness of Cavity & Core | 42-45HRC |

| Hardness of Wear Parts | 42-48HRC |

| Core pulling system | Motor /oil cylinder/ stripping plate, angel pin…etc |

| Mould Accessories | DME/HASCO Standard … |

| Molding life | 300,000-1,000,000shots |

| Runner | Cold or Hot |

| Delivery time | 15-45work days |

| Packing | Wooden case |

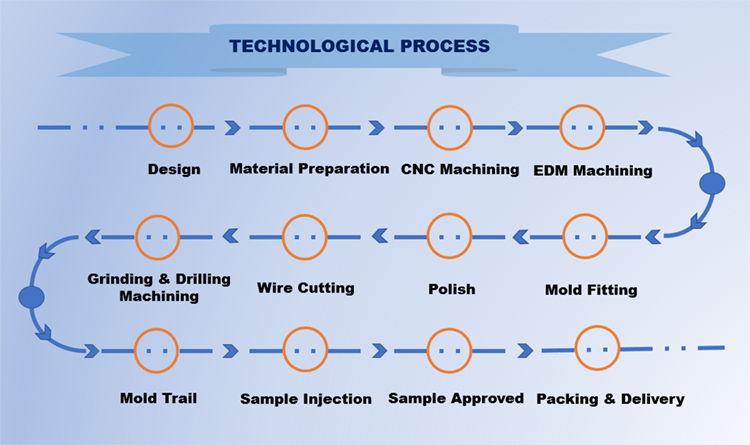

Plastic Bathroom Mould Produce Steps:

Our Factory Show:

Packing and Delivery:

FAQ:

Q: How many injection plastic mouldings machines do you have?

A: We have more than 50 plastic injection mold machines, variety of precision mold produce equipments and spray printing equipments.

Q: what is the minimum & maximum unit weight and size your machines can produce?

A: Our machines produce the unit parts from 1 gram to 6000 grams weight.

Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters.

Q: What kind of plastic materials you usually use?

A: We are specialized in producing plastic products with the following materials: PP, ABS, PC, POM, PA, HDPE, HIPE, PS, AS, PBT, PET, PMMA, PVC and so on.

Q: Can you deliver the plastic moulds or plastic products to our factory?

A: Yes, We have cooperated with many international logistics companies for years. And we have full experience to manage the delivery directly to the client's factory or appointed warehouse.