Plastic Mould Injection Molding For Exercise Bike Parts

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. One-stop Service:

Support plastic injection mold design and making service, plastic injection service, assembly work service, pad printing service, silk screen print service, paint service, ultrasonic welding service and packaging services;

2. Rich Experience:

more than 15years experience for plastic injection mould and plastic injection and developing capability;

High Quality, Competitive Price and Fast Delivery Time

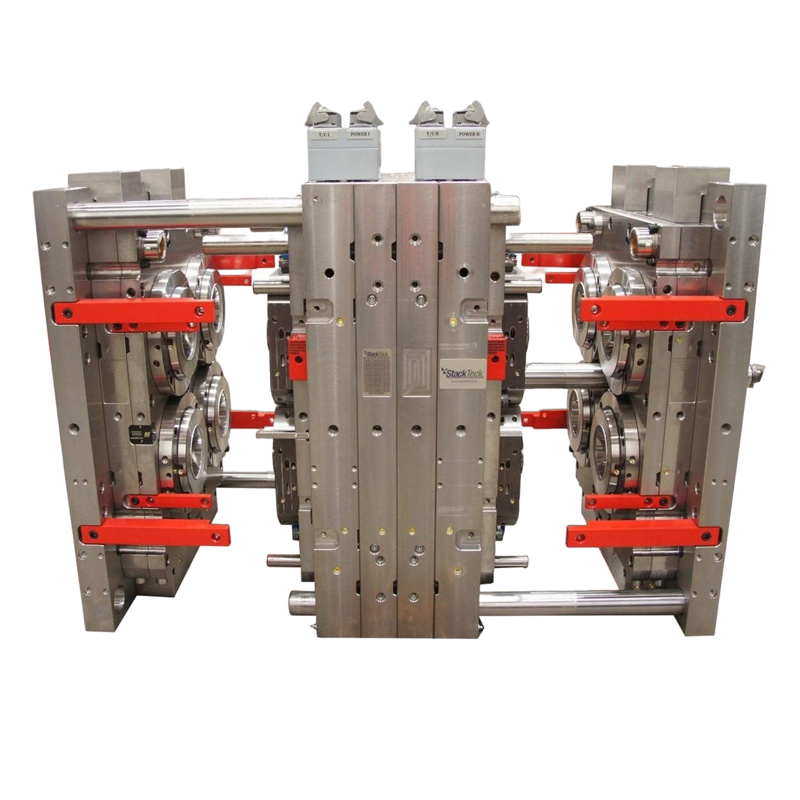

3. Advance Equipment:

Imported sophisticated production and testing equipment with high stability.

Plastic Mould Injection Molding for Exercise Bike Parts

Plastic Fitness Equipment Mould Description:

Product Name | Plastic Mould Injection Molding For Exercise Bike Parts |

Mold Base Material | P20/718/738/NAK80/S136/2738/2316/H13 etc. |

Mold Accuracy | +/-0.001mm |

Mold Life | 50K-1.5Million Shots |

Runner System | Hot runner/Cold runner or combined |

Mold Equipement | High speed CNC, EDM, Wire cutting, Grinding, Laser Marking, Drilling, Spotting machine |

Molding Facility | 60 TO 950T ton plastic injection machines |

Surface Treatmetn | Mirror Polishing, Texture MT(series), laser engraving, PVD coating, Nitriding |

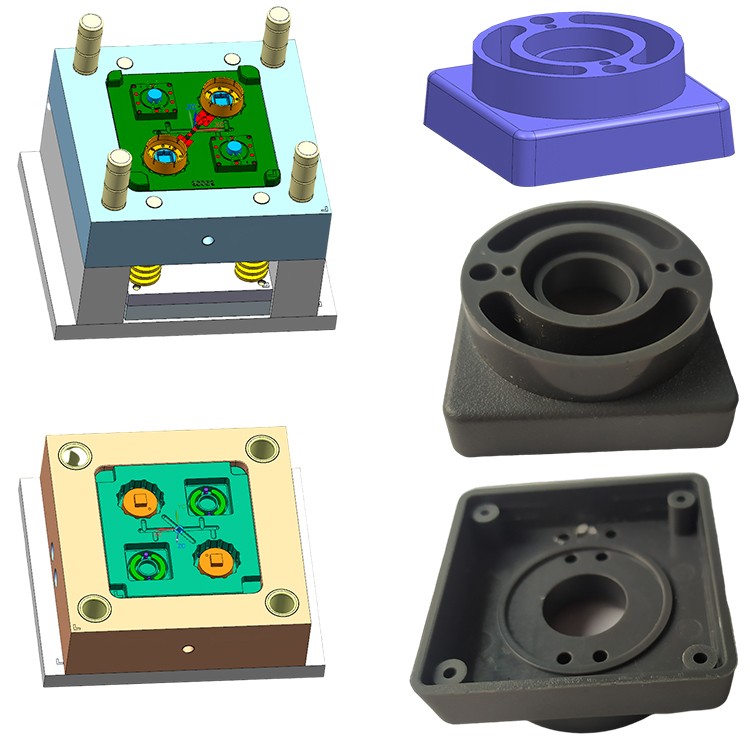

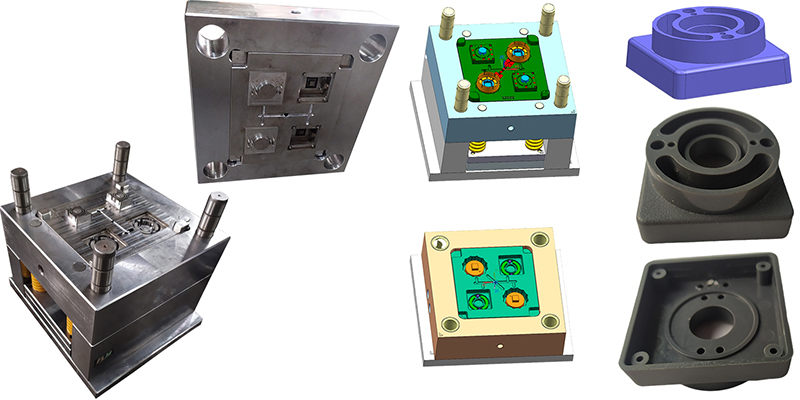

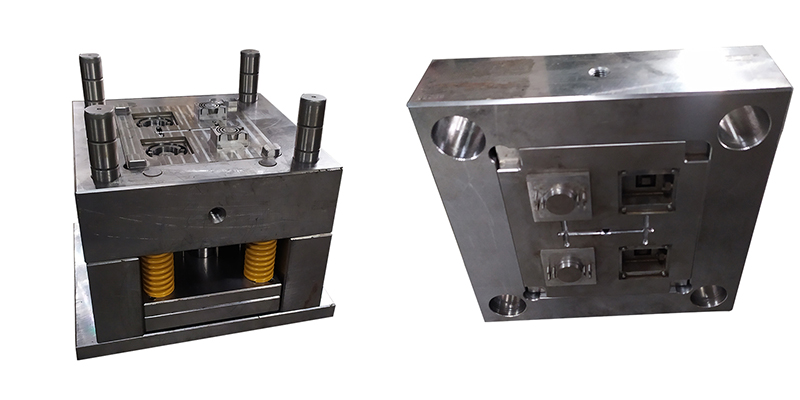

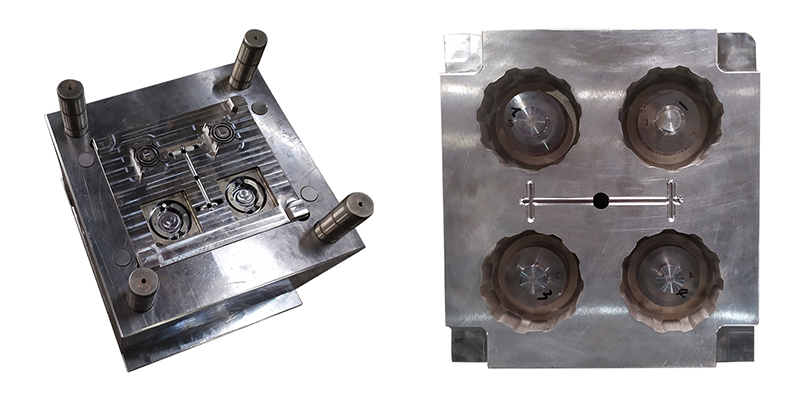

Plastic Fitness Equipment Mould and Products Show:

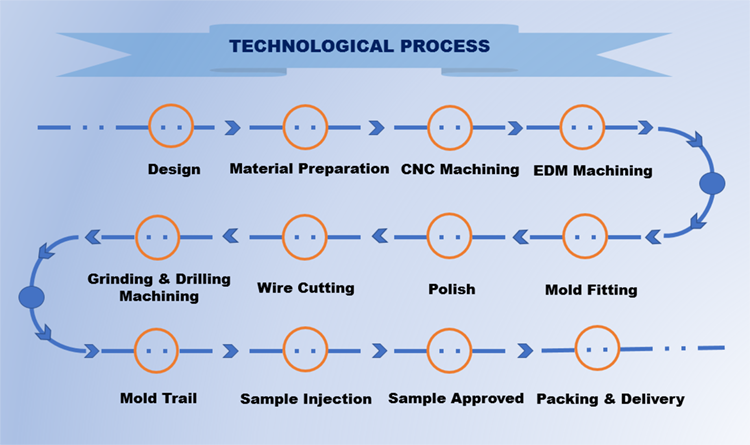

Plastic Fitness Equipment Mould Processing Flow:

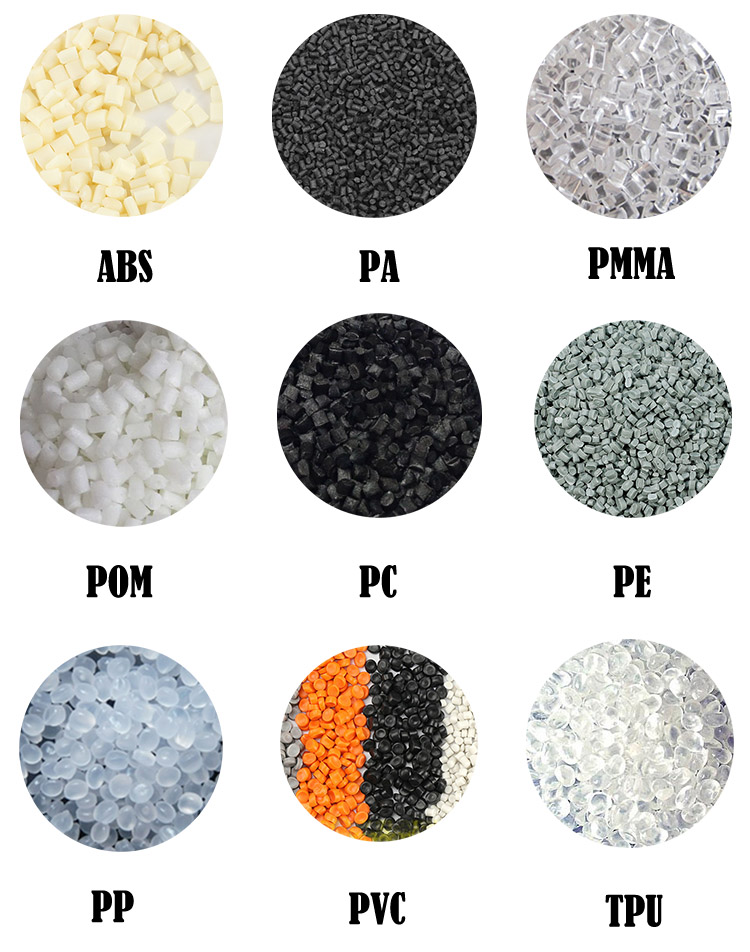

Plastic Raw Material:

The common material of the plastic parts as the following:

ABS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPS, PC, PPE, PPO, etc.

Plastic Fitness Equipment Mould Manufacturer Information:

We are a professional manufacturer of Plastic injection mould and plastic products express in plastic parts of sport equipment and plastic household products. Now we are one of the important manufacturers in sport equipment industry and plastic household industry. We also produce and sales plastic household products and plastic electronic products.

We are located in Xinglin development, Jimei district zone, Xiamen City. We have more than 50 plastic injection mold machines、variety of precision mold produce equipment and spray printing equipment. Our workshop area is about 7500 square meters and we have precision production equipment which reach the international advanced level and the experienced technician. Now our production value can reach 1.4 Billion RMB. “Quality first, continuous improvement, respect individual, team spirit” is our top management objective. We will make “build quality brand, service the needs of customers” as our guiding ideology. In connection with the requirement of domestic market and international market, we will take “excellent quality, perfect service” to meet the challenge actively to achieve our company top management goal --- continuity progress.

Packing and Shipping:

FAQ:

Q1: What kind of molds do you make? Plastic injection mold, Die casting mold or something else?

A1: We are mainly making plastic mold injection. Sometimes we also make Die casting mold and stamping molds according to our customer’s requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, we can provide steel certificate or hardness certificate to prove.

Q5: Can you make the texture / text / heat treatment /nitriding for the plastic injection mold?

A5: Yes, as plastic mold factory, we have long term cooperated subsidiary factories that do those processes. They are professional and well reputed in our local market.