Spare Parts Injection Vehicle Auto Plastic Mould

- Jinen/Jinjiekun

- Xiamen City, China

- 30 days

- 50 Sets Per Month

1. We have our own tooling shop, equipped with advanced machines for plastic injection mould and the plastic injection products.

2. We also have their own injection shop, to run the mold test & mass production for customers.

3. We have more than 15years experience for plastic injection mould and plastic injection.

4. We have precision production equipment which reach the international advanced level and the experienced technician.

5. ISO 9001 Certified for all of our plastic injection mould and plastic injection products and our factory;

Spare Parts Injection Vehicle Auto Plastic Mould

Plastic Auto Parts Mould Specification:

| Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.(Hardness 35~55HRC) |

| Mould base | Standard mould base,LKM, HASCO ect. |

| Cavity | Single or multi |

| Runner | Hot or cold |

| Surface treatment | Polish,texture,sandblasting,chrome |

| Mould life | 300,000-5,000,000 shots |

| Tolerance | 0.02mm -0.05mm |

| Pacakge | Standard export wooden case |

| Specification | Depends on customer's requirements. |

| Delivery time | Sample making 3-7 days,mold making 15-40 days |

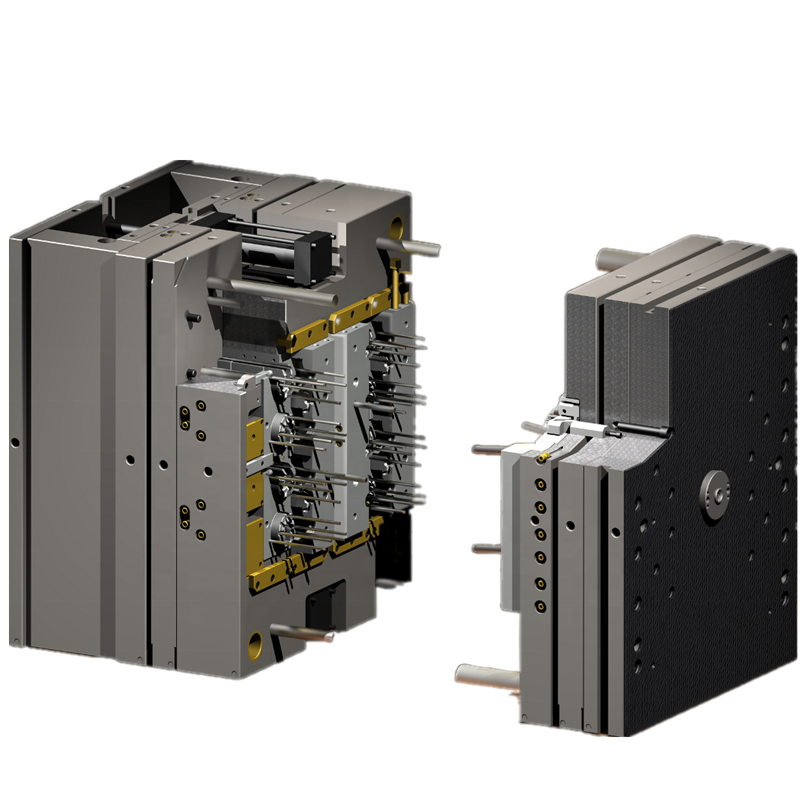

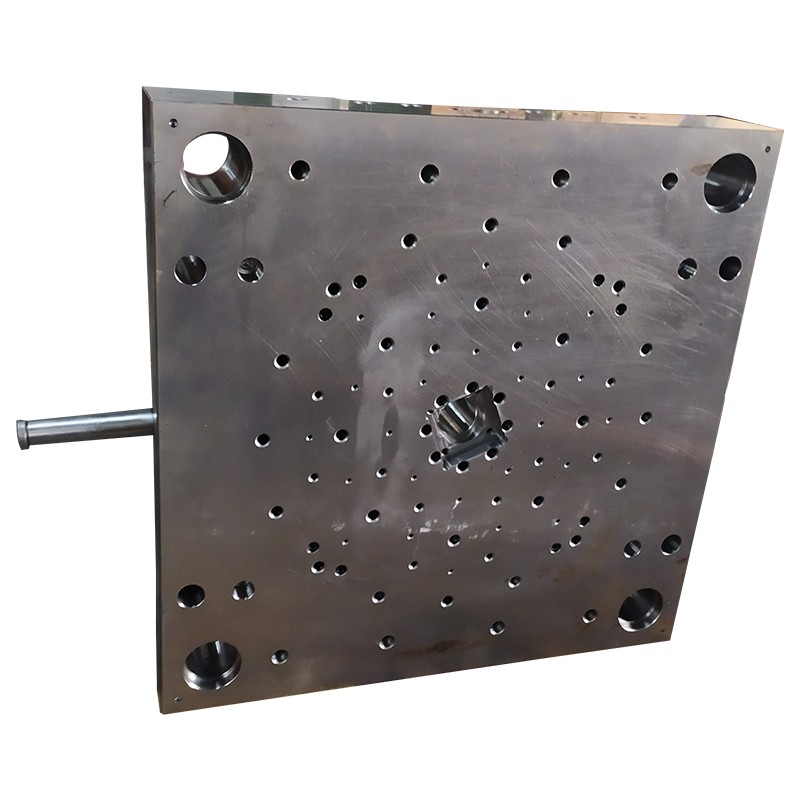

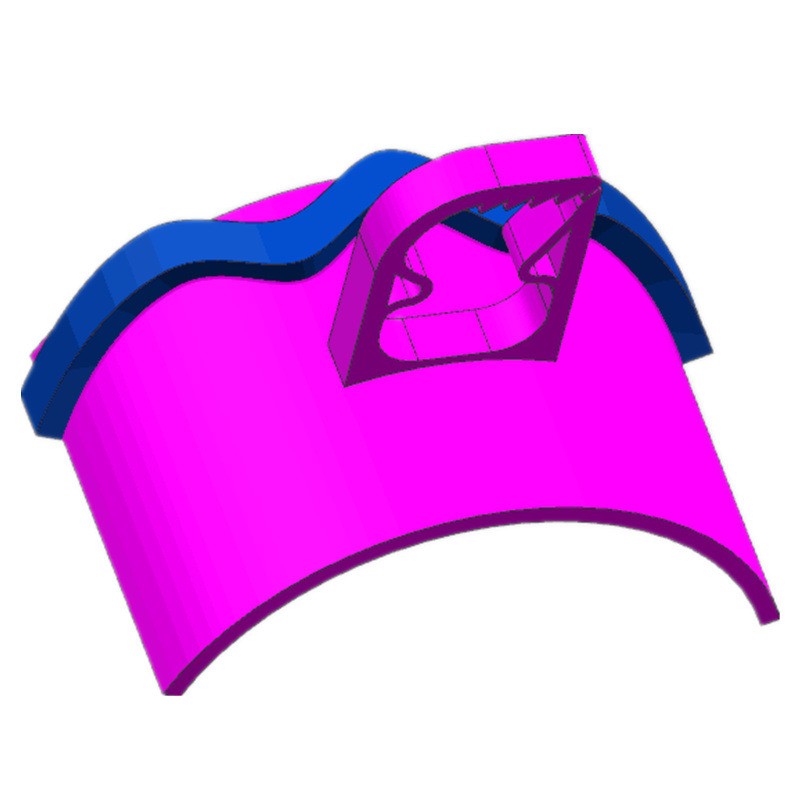

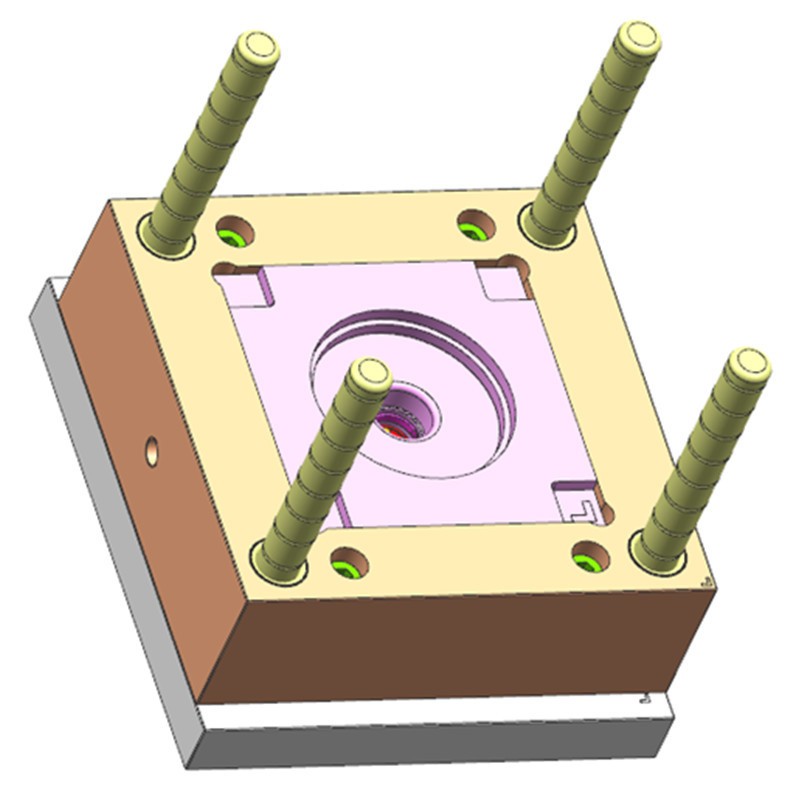

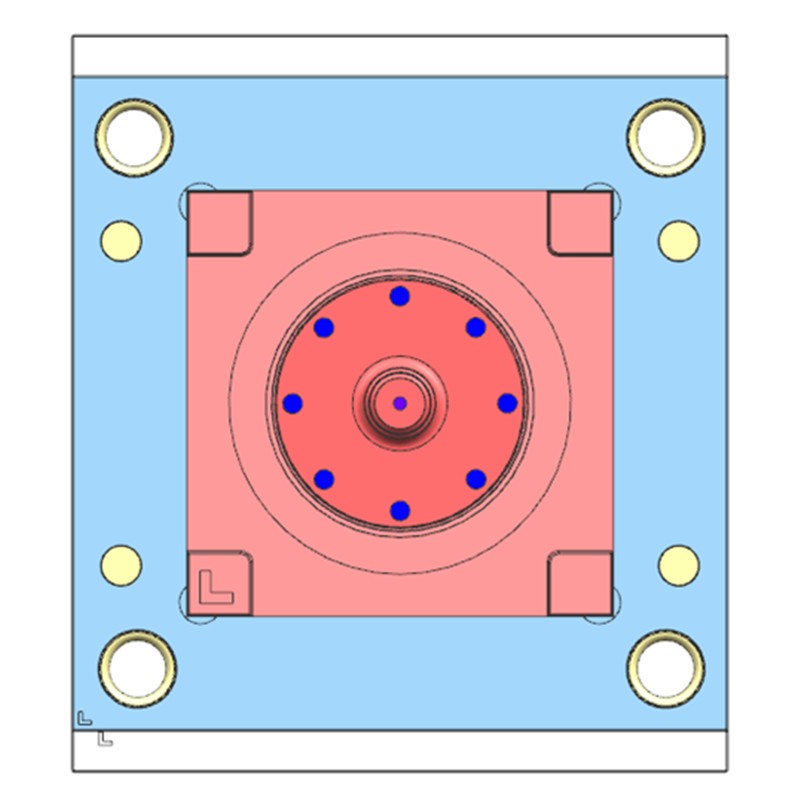

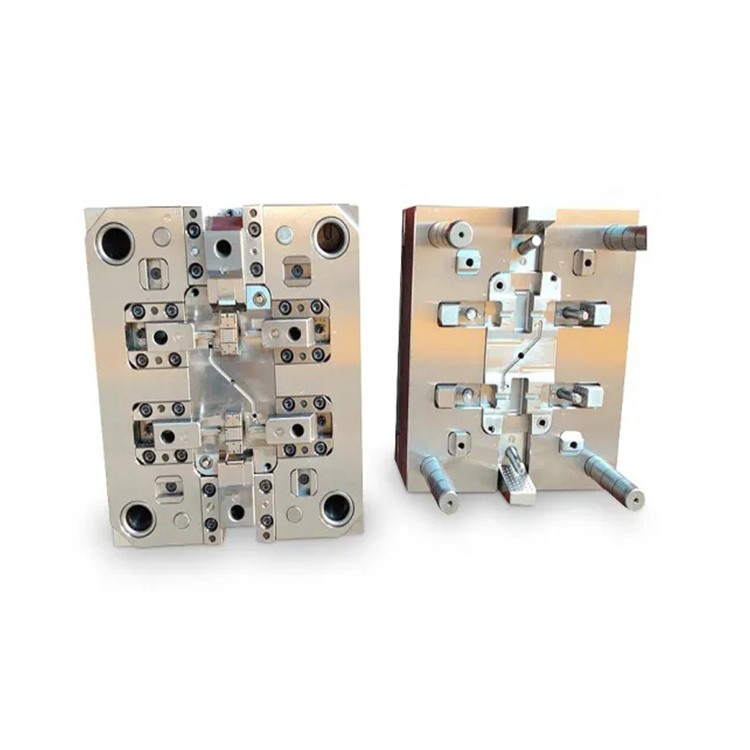

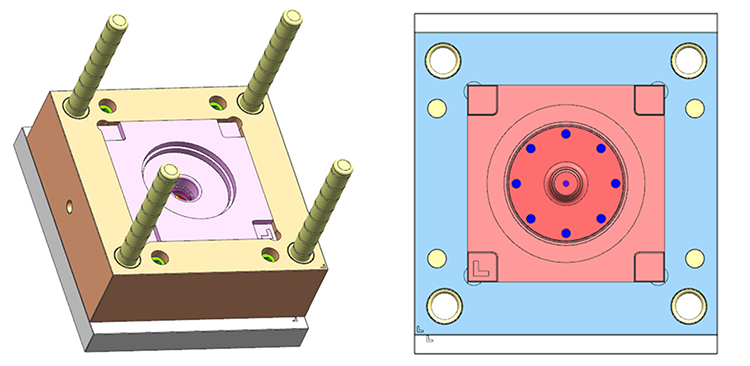

Plastic Auto Parts Mould and products Show:

Our Service:

Plastic Auto Parts Mould Factory Information:

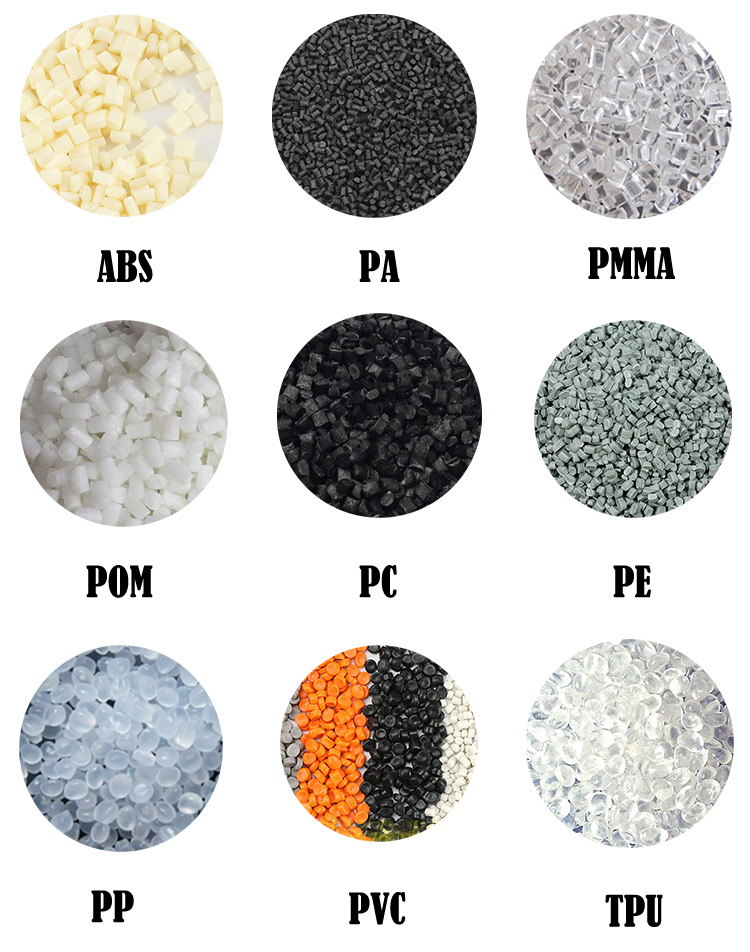

Plastic Raw Material:

FAQ:

Q : How can I get your quotation ?

A : Please provide us information as below :

1) 3D Drawing (STEP, IGS, STL) or 2D/images with Dimension

2) Product Material you are into or suggested by us and Order Quantity

Q: How you do the quality control?

A:

1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out.

Q: What should we do if we receive defective products?

A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q: How to pack the moulds and products?

A:

1). For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer’s request to pack.